Light alloy wheels painting

IN Automotive

Investor Name:

Published Date:

1 January 1970

Location:

Value:

Architecture:

About Project

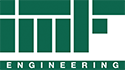

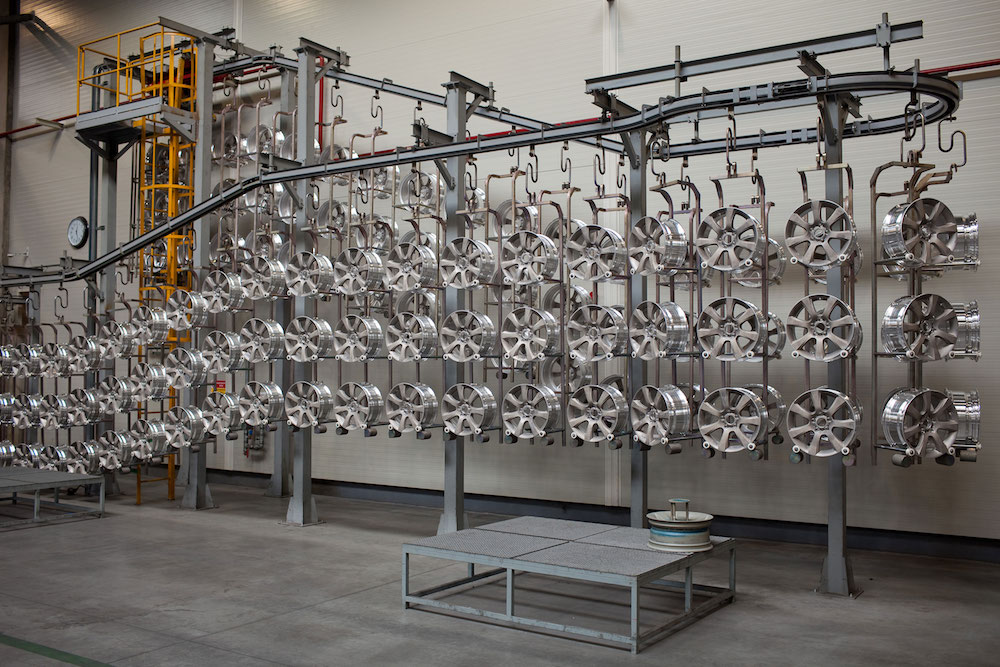

For the automotive industry, IMF ENGINEERING produces painting plants for light aluminum alloy wheels. Our equipment consist of: pre-treatment and drying tunnels, clean rooms, spray booths pressurized and conditioned for electrostatic powder coating and liquid painting, both using solvent-based paints and water-based paints, curing ovens for both powder and liquid paint, cooling systems.

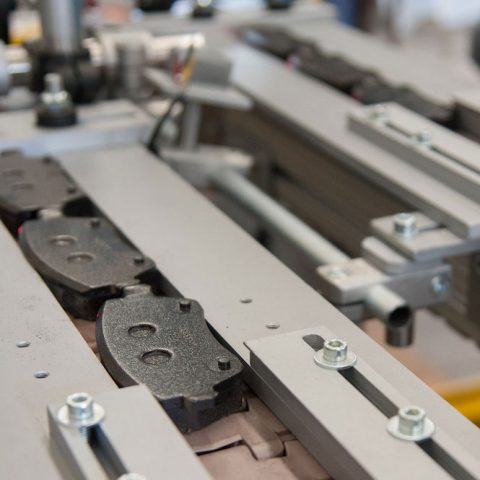

Each phase of the process runs in protected and conditioned rooms and supported by specific robotic automation, necessary for the safe transfer of the wheels and for the high quality of painting required. The application of the paint is performed by the best application systems available today on the market, such as the CORONA technology application for the powder coating, as well as liquid electrostatic painting, also with rotating bells, capable of reaching and covering even the most complex shapes of the wheels in the best possible way. Depending on the size of the plant and the required production quantity, the application systems can be equipped with suitable robotic painting automation.

The curing ovens we produce, in total respect of the required time and temperature curves, increase the adhesion of the paint to the metal support and its resistance to corrosion, according to the strictest specifications of the Original Equipment Manufacturing sector. We manufacture all our ovens and cooling tunnels focused on energy saving, through the choice of materials and design selected to achieve this goal.

The wheel painting plants can also be equipped with systems for the treatment of the emissions in the air (thermal, catalytic, regenerative combustor) and in the water (paint sludge removing, chemical / physical treatment).

To support immediately our customers we can also provide the remote assistance of our plants for prompt service contact.